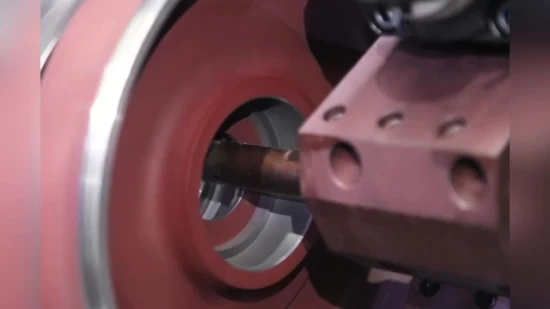

Qizhi CNC Pressure Vessel/ Boiler Nozzle Automatic Welding Machine

QIZHI CNC Pressure Vessel/ Boiler Nozzle Automatic Welding Machine-QZMAH300 1. Key Features The specially designed saddl

Description

Basic Info.

| Model NO. | QIZHI MAH300 |

| Color | Medium Gray |

| Welding Method | Saw |

| Relative Humidity | ≤ 85% |

| Working Environment Temperature | -5 ºC~+45 ºC |

| Transport Package | Wooden Case |

| Trademark | QIZHI |

| Origin | China |

| HS Code | 85153900 |

Product Description

QIZHI CNC Pressure Vessel/ Boiler Nozzle Automatic Welding Machine-QZMAH3001. Key Features

- The specially designed saddle shaped Curvilinear motion mechanism is easy to adjust and reliable.

- The saddle drop can be adjusted from 0 to the corresponding range, and the machine head can be used for flat rotation welding and saddle welding (under preheating conditions of the workpiece).

- Rotating components are with stepless adjustable rotation speed.

- The horizontal and vertical positions of the welding torch are manually adjusted (non-automatic adjustment), ensuring reliable control.

- It can achieve multi-layer and multi-pass continuous welding.

- The equipment is equipped with a rotating conductive current collection device, and the wires are not entangled during multi-layer and multi-pass continuous welding.

- The rotating conductive device adopts a dual wire and dual brush structure to ensure good conductivity.

- To prevent excessive number of conductive rings, the control system is installed on the equipment body and rotates with the equipment.

- It can work for a long time under the condition of workpiece preheating ≤ 200 ºC.

| Item | Name & Description | Parameters |

| 1 | Model | QZMAH300 |

| 2 | Nozzle outer diameter | 100~300 mm |

| 3 | Saddle drop | 0~50mm |

| 4 | Workpiece max. preheating temperature | 200ºC |

| 5 | Wire dia. | Φ1.2 mm, Φ1.6mm |

| 6 | Welding torch angle | ±5° |

| 7 | Rotating speed | 0.2~2 rpm |

| 8 | Duty cycle | 400A @ 100% |

| 9 | Nozzle height | 150~200mm |

3. Application This machine is mainly used for welding the nozzle which can NOT connect with flange in orthogonal and eccentric situations on pressure vessel, boilers or cylinders. Welding process is Submerged arc welding.

Prev: X Y Axis CNC Automatic Spot Welder Multi

Next: Large 5 Axis CNC Mould Making Machine, Foam Ship Mold Milling Machine

Our Contact

Send now