Horizontal Small Flat Bed Metal Turning Bench Lathe Machine Center Slant Bed CNC Lathe Swiss Lathe

Description

Basic Info.

| Power Source | Electric |

| Controlling Mode | CNC |

| Automatic Grade | Semiautomatic |

| Setting Mode | Floor-type |

| Precision | High Precision |

| Certification | CE, ISO 9001 |

| Condition | New |

| Guideway Width | 755/1100mm |

| Pipe Threading Range | 130~630mm |

| Max. Swing Dia. Over Bed | 1000/1200/1400mm |

| Center Distance | 1500/3000mm |

| Chuck Size | 800/1000/1250mm |

| Spindle Bore | 280/330/390/440/520/640mm |

| Spindle Motor Power | 22/37kw |

| Transport Package | Wooden Case |

| Specification | 500*320 |

| Trademark | Jepps |

| Origin | China |

| HS Code | 8458110090 |

| Production Capacity | 500units/Year |

Product Description

Product DescriptionGuideway width 550/600mm

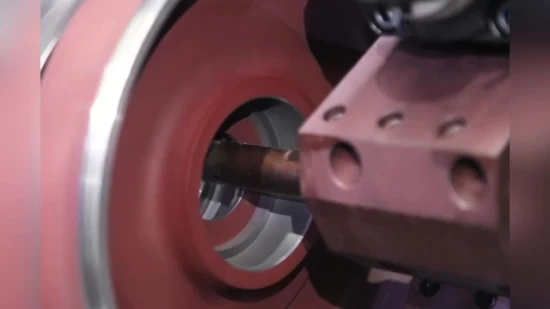

- Suitable to process internal thread and external thread of pipes, can be also used as standard cnc lathe

- Adopt China top quality compound resin sand cast iron,after aging treatment,good precision keeping

- Guideway hardened by ultrasonic frequency, good precision keeping, long using lifespan

- Guideway stick PTFE,remove creeping,good wearability

- Adopt gear spindle, stepless speed in every class

CNC Lathe Features

2.High accuracy Taiwan linear guideways

3.Chip conveying capacity is large and convenient ,customer could choose chip conveying in the right or in the back

4.Spindle unit has two types ,the heavy duty cutting type and the high speed type.

5.The first one is suitable for bearing and gear processing .

6.The second type is suitable for high speed and jhigh precision processing.

7.Customers could choose any type of them

8.Screw pre-stretching structure

9.Gang type tool post10.Optional turret

High Precision Slant Bed CNC Lathe CNC Turning Center

Product Description

| Specificationj | Unit | QK1319 | QK1322 | QK1313 |

| Hole through spindle | mm | 200 | 200 | 135 |

| Max .processing Pipe diameter | mm | 196 | 196 | 130 |

| Max. swing over bed | mm | 600 | 630 | 500 |

| Max. swing over carriage | mm | 340 | 350 | 340 |

| Distance between center | mm | 1500 | 1500 | 1500 |

| Max. work piece length | mm | 1350 | 1500/3000 | 1350 |

| Guideway width | mm | 460 | 460 | 460 |

| Number of spindle speed changes | mm | |||

| Range of spindle speed changes | r/min | 18-600 | 24-800 | 24-800 |

| Quick travel speed (X/Z) | mm/min | 6000 | 6000 | 6000 |

| Max. travel | mm | 390 | 420 | 390 |

| Tool post style | ||||

| sectional dimension of knife | mm | 32*32 | 32*32 | 32*32 |

| Taper of the tailstock | MT5 | MT5 | MT5 | |

| Diameter of the tailstock | mm | 75 | 75 | 75 |

| Travel of the tailstock | mm | 230 | 230 | 230 |

| Power of main motor | kw | 11KW | 11KW | 11KW |

| X axis servomotor | kw | 1.5KW | 1.5KW | 1.5KW |

| Z axis servomotor | kw | 2.3KW | 2.3KW | 2.3KW |

| Cooling pump | kw | 0.125KW | 0.125KW | 0.125KW |

| Processing workpiece precision | IT7 | IT7 | IT7 | |

| Workpiece surface roughness | Ra1.6 | Ra1.6 | Ra1.6 | |

| Length of bed | mm | 3600 | 3600 | 3600 |

| Width of bed | mm | 1560 | 1560 | 1560 |

| Height of bed | mm | 1600 | 1600 | 1600 |

| Weight of bed | Kg | 3000 | 3000 | 3000 |

| NC system | GSK/FANUC/SIEMENS | |||

| Weight capacity | Kg | 4600 | 4700 | 4500 |

2. The machine bed is an integral floor structure, which greatly improves the rigidity of the machine tool. The width of the guide rail surface of the bed is wide, and has been quenched and precision ground by super audio frequency.

3. Quenching precision grinding gears and high-quality bearings to ensure low noise and good sound quality of the machine tool.

4. The spindle box adopts powerful external circulation cooling and lubrication, which not only reduces the temperature rise of the spindle, but also maintains the cleanliness and lubrication of the spindle box.

5. The X and Z axes are directly driven by high-precision ball screws and pre-stressed and tightened, and the nut hanger is an integral structure.

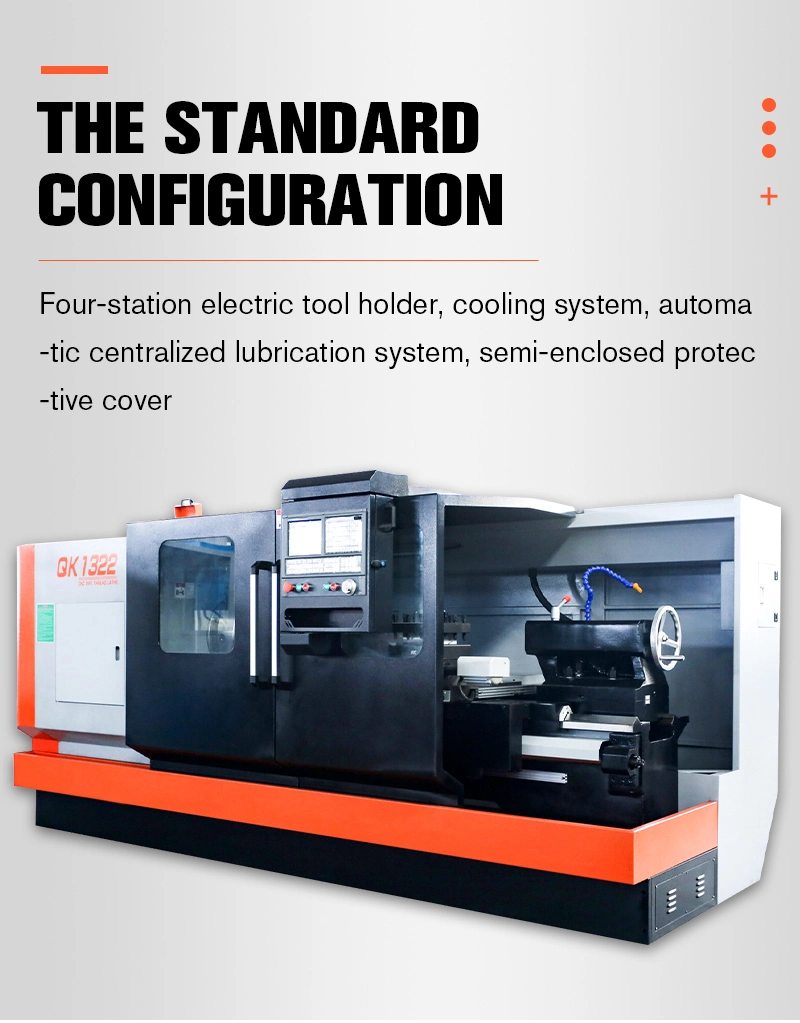

6. The large-size 4-station vertical electric turret enables the machine tool to have high processing efficiency and more effectively ensure the precision of the inner hole thread of the fine turning.

Standard configuration:

- GSK980TC3 CNC controller - Double Manual chuck - 4 station tool post- Manual tailstock

Optional configuration:

- SIEMENS 808D ADVANCED/FANUC 0I TF controller - 6/8 station tool turret

FAQ

1

Q: Which trade term I can choose?

A: You can choose FOB,FCA

2

Q: How can I get quotation from you?

A: You can make the inquiry online on made-in-china, or send email to us. It is better if you can tell what is your detailed request information. We will reply to you within 24 hours on work days, and within 48 hours on holiday.

3

Q: how can I make the payment?

A: You can pay by T/T . You can also pay to my company business bank account.

4

Q:What is your delivery time ?

A:The delivery depends on different machines with different configurations. Please contact us to confirm it is in stock or not.

We want to know:Please tell us your specific purchasing requirements, so that we can make specific quotations.

Next: Dmtg Cke6150z Horizontal Small Flat Bed Metal Turning Bench Lathe Machine Center Slant Bed CNC Lathe

Our Contact