Full Automatic Wheel Cutting CNC Turning Milling Vertical Lathe Machine

Full Automatic Wheel Cutting CNC Turning Milling Vertical Lathe Machine 1.Product Description This machine is an automat

Description

Basic Info.

| Model NO. | VTC70 |

| Power Source | Electric |

| Controlling Mode | CNC |

| Automatic Grade | Automatic |

| Setting Mode | Floor-type |

| Precision | High Precision |

| Certification | CE, ISO 9001 |

| Condition | New |

| Rapid Traverse Speed Vertically | 16000 |

| Diameter of Hyaraulichuck | 400/500 |

| Rapid Traverse Speed Horizontally | 16000 |

| Maximum Rotating Diameter of Machine Too | 700 |

| Cutting Feed Speed | 0.1~1000 |

| Apindle Speed Range | 100~1000 |

| Transport Package | Transparent Plastic Wrap, Plywood Wooden Case |

| Specification | 2050*1800*3200mm |

| Trademark | ZYZG |

| Origin | China |

| HS Code | 8462919000 |

| Production Capacity | 50 Sets/Month |

Product Description

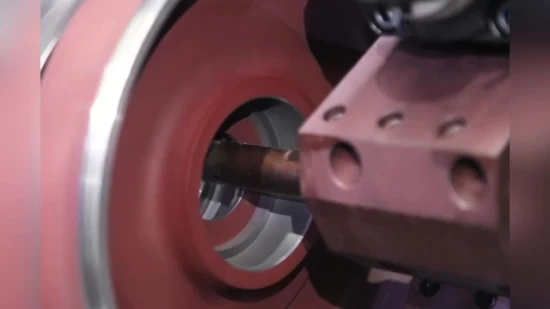

Full Automatic Wheel Cutting CNC Turning Milling Vertical Lathe Machine1.Product Description This machine is an automatic vertical cnc lath for machining the inner and outer cylindrical surfaces of the parts, conical surface, end surface, grooving and chamfering. It is especially suitable for drums, clutch pressure plates ,flywheels and alloy wheels repairing.

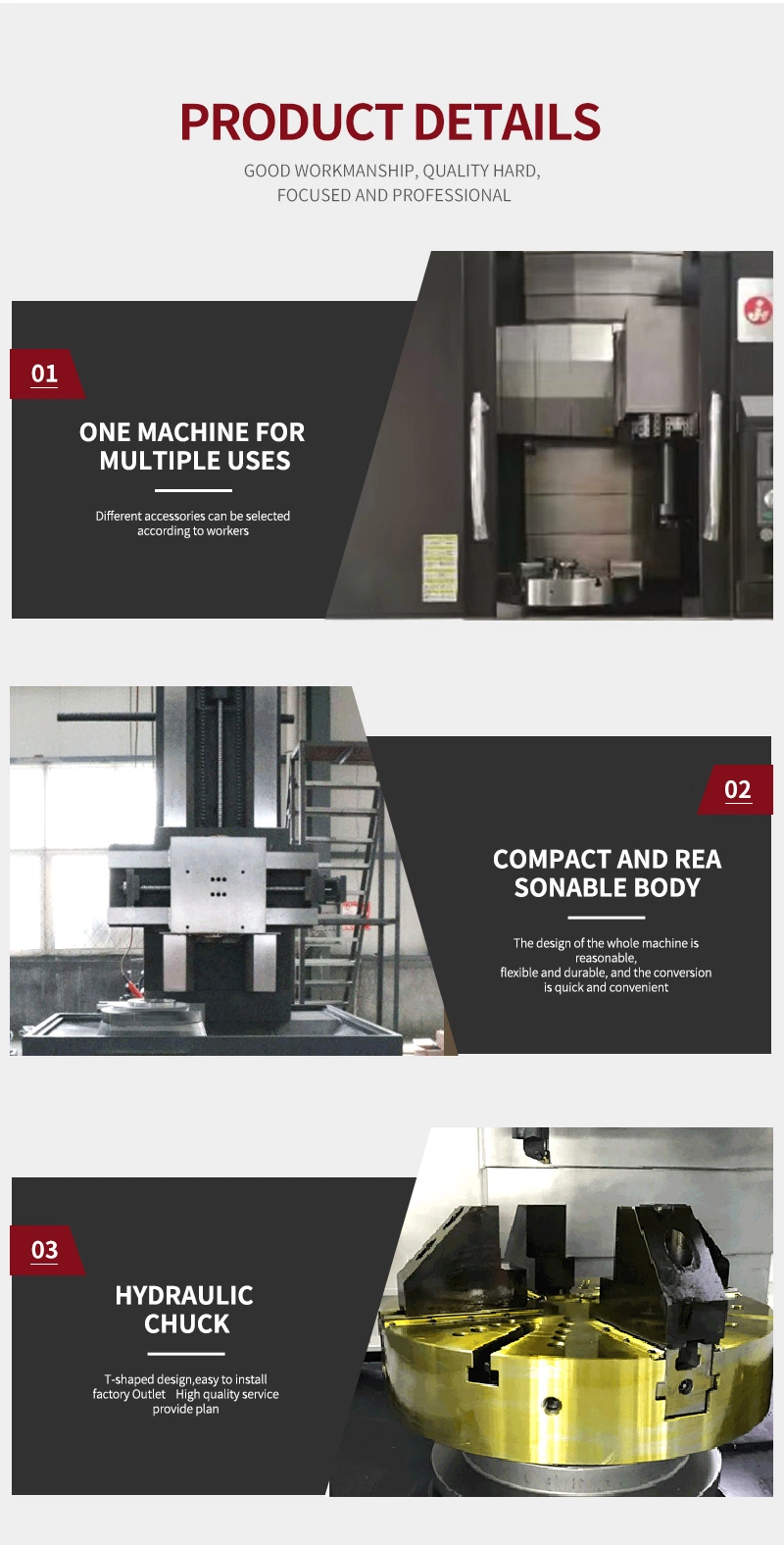

2.Main Features

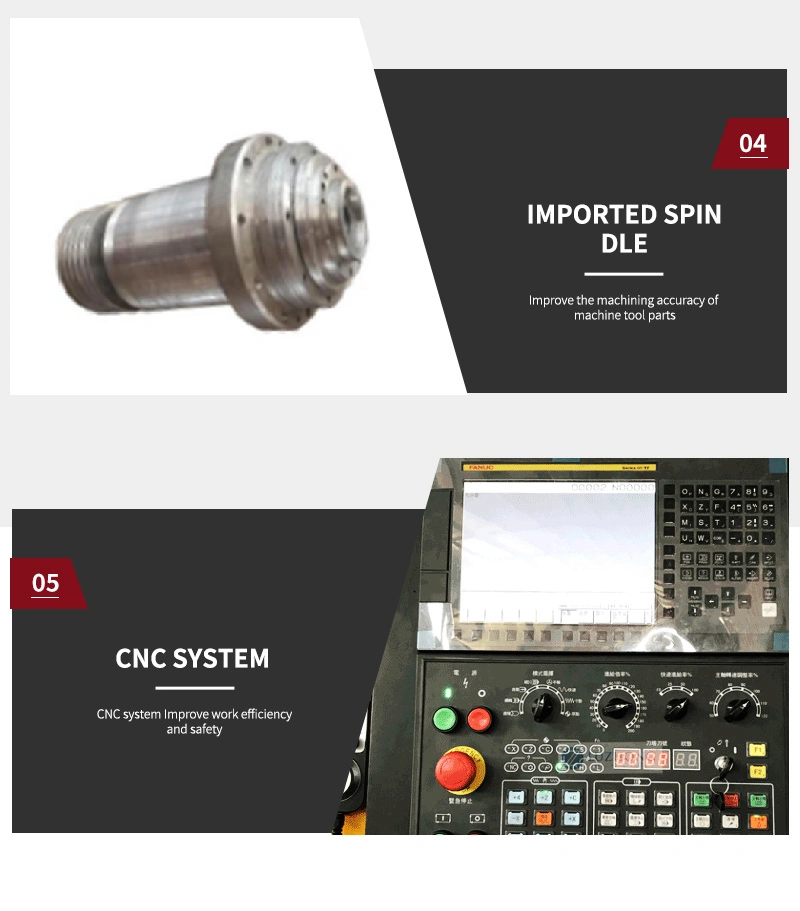

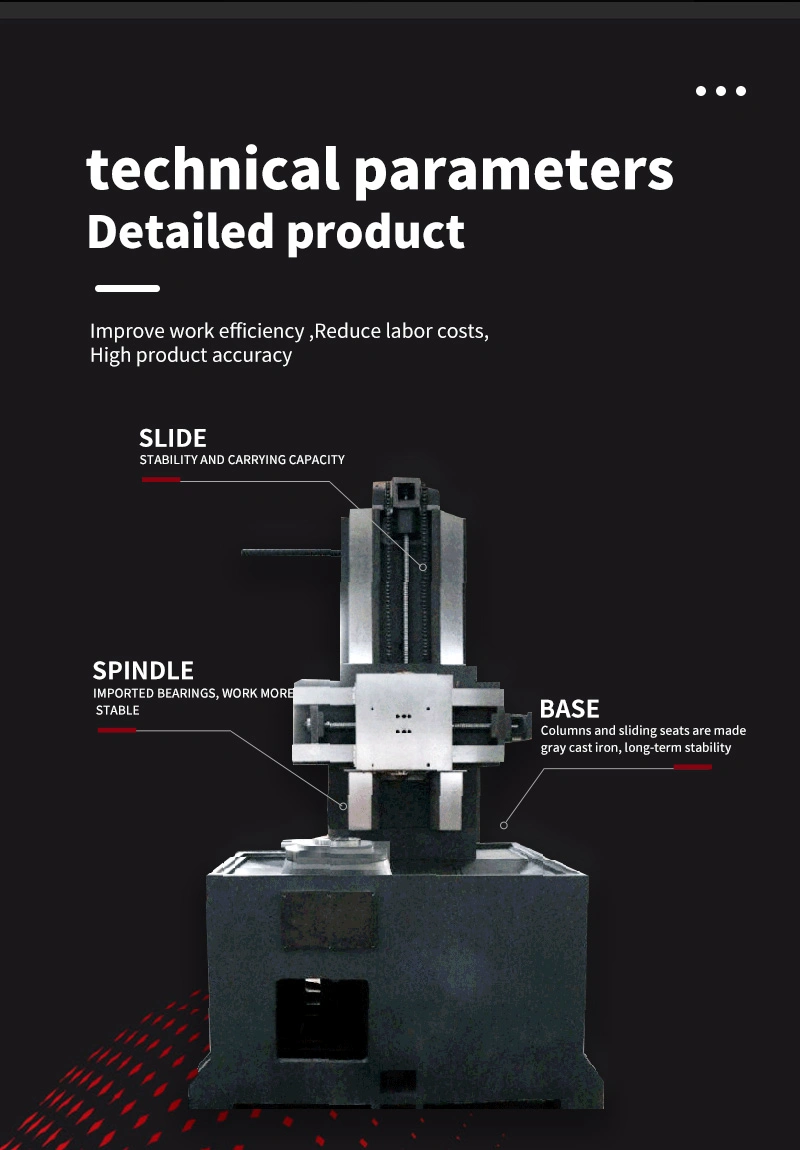

1. The machine tool is of roller type linear slide rail, with ultrahigh rigidity and overload capacity, substantially improving positioning accuracy and bearing capacity in regard to vertical and horizontal feed movement.2. The machine tool spindle belt pulley is connected with that of spindle numerical control servo motor through belt, equipped with 22Kw motor for infinitely variable speed of wide range, satisfying different spindle speed required for parts rough machining and finish machining.3. Both the vertical and horizontal feed is controlled by servo motor automatically. The vertical direction setting Balance weightstructure greatly extend the life cycle of lead screw4. Automatic tool holder: the tool and detection station conversion can be realized by CNC system.5.Automatic lubrication system is used for main moving parts.6.Can choose different machine appearance.

3.Specification

| Specification | UNIT | VTC70 | VTC80 |

| Max.Swing diameter | mm | 700 | 800 |

| Spindle speed | rpm | 100~1000 | 100~800 |

| Cutting feed speed | mm/min | 0.1~1000 | 0.1~1000 |

| Vertical moving distance of tool holder | mm | 700 | 800 |

| Tool rest horizontal moving distance | mm | 700 | 550 |

| Longitudinal fast moving speed | mm/min | 16000 | 16000 |

| Transverse fast moving speed | mm/min | 16000 | 16000 |

| Tool holder form | horizontal | horizontal | |

| Diameter of hydraulic chuck | mm | 400/500/630 | 400/500/630 |

| Main motor power | Kw | 22 | 22 |

| positioning accuracy | mm | ±0.008 | ±0.008 |

| Re -positioning accuracy | mm | ±0.004 | ±0.004 |

| Machine size | mm | 2050x1800x3200 | 2050x1800x3200 |

CNC vertical lathes are suitablee for processing motor end cover, electric housing, wheel hub, brake hub and other types of short shaft, pump body, disc parts.Suitable for multi-variety, small and medium-sized batch parts processing characteristics, is the automobile, agricultural machinery, engineering machinery, electrical machinery and other industries parts processing preferred equipment.

5.Packaging Details

Packaging Details1. Packing method: Internal plastic moisture-proof anti-rust packaging, External wooden packaging, Exclusive container transport.2. Mode of transport: by sea or by land. 6.Our services

Our services are divided into pre-sale, sales, after-sale three parts. Pre-sale:to provide detailed advice, the program recommended to the factory inspection, as far as possible to meet your questions and needs.Sales:can support samples, support diversified payment methods, the solid forklift tire press machine production processtransparent,standardized and quickly stocking.After-sales:support diversification guidance, training, voice and video images, and even solid forklift tire press machine overseas site installation, on-site training, home maintenance, continuous return visit customers concerned about the use

7.Company information

Our company has passed the ISO quality management system certification,Products are exported to more than 50 countries and regions including Europe, America, Asia, Oceania and Africa.Has a number of product patents and honor certificates,is a continuous innovation machinery and equipment company.

8.FAQ

1:How can I choose the most suitable machines ?

A: Please tell me your specifications ,we can choose the best model for you , or you can choose the exact model .You can also send us the products drawing ,we will choose the most suitable machines for you .2: How can I get a quotation?

A: Pls tell us the machine you need, including quantity, raw materials and other requirements.

3: Where is your factory located? How can I visit there?A : Our factory is located in Tengzhou City ,Shandong Province,277500 China. You are warmly welcomed to visit us.4. What is your trade terms?A : FOB, CFR and CIF all acceptable.5:How can i trust your company?

A:We have professional design, we can provide you suitable suggestion and lowest price1. Assessed by third party, national patents and CE, ISO for all equipment, .

Our Contact

Send now